PROJECT DETAILS

Place of application: Oil Field Poddvorov

Used Cleaning Technology: Downhole equipment cleaning (rod string and tubing) with DIR-X (during production)

The well was cleaned once per year from 2014 to 2021 to date

Well Parameters

Well depth 1500 m, reservoir temperature 54 °C, pump setting depth 1200 m, there was a problem with paraffin deposits

Standard cleaning method 4 day workover / intervention): pull the rod pump and tubing out of the hole, cleaning with steam from paraffin at the surface, casing cleaning with scraper and hot oiling.

Cleaning Process – Heating up the downhole completion during production

Mixture quantity: 4.8 m3

Cleaning time: 3 hours

Pump DIR-X down the annulus to heat up the entire 1200 meters of well downhole completion

Process:

- the well is connected to the central pipe line system (gathering station)

- well production is switched to the separate tank during application

- dynamic fluid level 1 050 – 1 100 m

- pump DIR-X (4.8 m3) down the annulus

- the chemical reaction is divided into four time periods (16, 12, 6 and 2 minutes) after the reaction brake (10 minutes), pump 10 m3 of oil down the annulus to wash out the spent DIR-X with melted aparaffin deposits out of the well to the tank

- reconnect the well to central production pipe line and restart oil production

Result of Cleaning

Circulation pressure after cleaning was much lower. After 3 hours of well cleaning with DIR-X well production was restored to designed capacity and normal operation conditions in a very short time and with lower costs.

Well cleaning with DIR-X is currently performed once per year. The run life – interval between interventions – was increased from 2 years to 5 years.

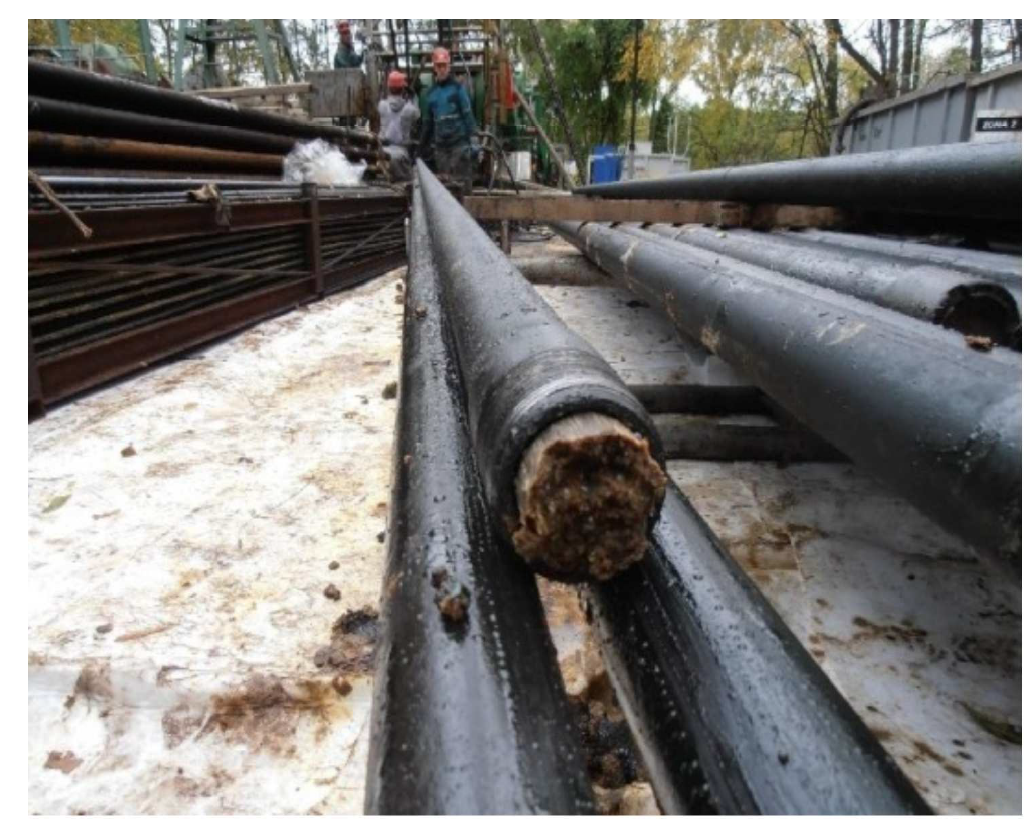

Nr.1 Clogged production tubing

Nr. 2 Melted paraffine from the well during cleaning TERMO-U